About us

Company profile

- UNIVERSAL Inc.

- Est. August, 2006

- CEO: Hiroshi Irie

OFFICE & FACTORY

- ADD: Chikumazawa983-1, Miyoshi-cho, Iruma-shi, Saitama, 354-0043 Japan

- TEL. +81-49-259-3230 (Japanese only)

- FAX. +81-49-259-3293

* We only handle inquiries in Japanese via telephone.

Corporate History

August, 1996

Founded as a optical parts processor, mainly engaging in polishing of optical lenses.

December, 2004

Switched to the industry of precision parts processing, by introducing a machining center.

May, 2015

Transferred to the current corporate address in order to expand the corporate factory.

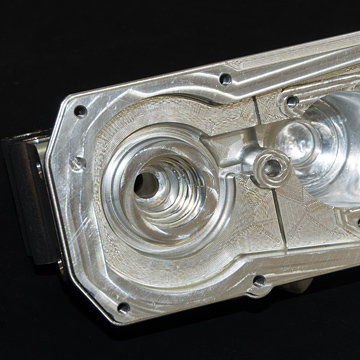

Major Products

- Developed and racing parts for four-wheel vehicles

- Developed and racing parts for motorcycles

- Optical measurement instrument parts

- Semiconductor manufacturing equipment parts

- Vacuum equipment parts

- Medical equipment parts

- Shaving molded parts

Line of Materials

- General steel (up to about HR60)

- Stainless-steel

- Aluminum

- Magnesium

- Copper alloy

- Titanium

- Resin

- Other metals

Major Equipment and Facilities

| Machines | Machine name / Software title | Manufacturer | Specifications |

|---|---|---|---|

| 5-axis machining centers | a61nx-5E(details) | MAKINO MILLING MACHINE | HSK-A63, 20000rpm, 2APC 0.5μ scale feedback, High-precision bearings, Built-in inhale |

| NMV5000(details) | DMG Mori Seiki | BBT40, 20000rpm, equipped with lathe turning | |

| D300 | MAKINO MILLING MACHINE | HSK-A63, 20000rpm, 2APC 0.5μ scale feedback | |

| Vertical machining centers | MB56-VA | OKUMA | BBT40, 15000rpm, Automatic measuring, Scale feedback |

| MB56-VA | OKUMA | BBT40, Dividing 4-axis 15000rpm, Center through, Automatic measuring, Scale feedback | |

| Horizontal machining centers | a71nx | MAKINO MILLING MACHINE | BT50, 10000rpm, 2APC 0.5μ scale feedback, Built-in inhale |

| Combined processing machine | MULTUS U3000 | OKUMA | 10-inch chuck, HSK-A63, 12000rpm, 5-axis simultaneously processable specification, Gear machining package |

| NC lathes | LB3000EX | OKUMA | 8-inch chuck |

| CNC 3-D measuring machine (★) | CRYSTA-Apex S9166 | Mitutoyo | Copy measurement, Free-form surface evaluation measurement |

| Manual 3-D measuring machine (★) | QMM-353 | Mitutoyo | |

| DIGIMICRO (★) | MF-501 | Nikon | 150 mm height measurement |

| CADCAM systems | HyperMill | OPENMIND | 5-AXIS CATIA direct I/F |

The (★) mark indicates measuring equipment.

UNIVERSAL's Metal Processing Work

UNIVERSAL Inc. manufactures and quickly delivers high precision prototypes for various R&D institutions, including automobiles, aircrafts, and spacecrafts.

■ Quick delivery: 5 days is the average delivery time from reception of your order in the Kanto Region.

■ Advanced skills based on solid know-how: We are able to finish complicated shapes and shave materials with high precision.

■ Organized workspace: We maintain the temperature in our workspace at 24°C by turning on air conditioning 24/7.

Commitment to 5-axis Processing

Even as a small company, our factory is equipped with vertical and horizontal 5-axis machining centers which are usually difficult to operate and handle. Making such efforts, we commit ourselves to improve finishing precision on a daily basis.

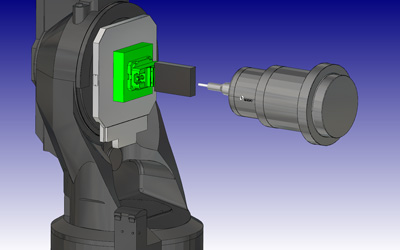

Two Types of CADCAM Software

By using the proper software of the two different types of CADCAM according to processing, we provide the needed precision at the shortest lead time for customers (3-axis FeatureCAM/5-axis Hypermill).

Selected Cutting Tools

In order to offer high-precision finishing, we always have a collection of cutting tools and holders in the needed quantity that are procured from overseas manufacturers ready for use.

NC Circular Tables for Vertical Machines

Our vertical machines are equipped with circular tables so that we can support 4-axis processing.

Dividing and Simultaneous 5-axis Processing is also always ready.

We support both dividing 5-axis processing and simultaneous 5-axis processing.

Scale Feedback is Fully-Equipped

Our machines are equipped with scale feedback/high-speed main axes (20000rpm).

HSC Supported

CADCAM supports HSC (*1), while being capable of outputting rough processing data at a high speed. This system thus reduces processing time and creates high-quality finishing data.

*1 HSC: High-speed Cutting Cutter Path

*2 Advanced to the domain of processing lightweight parts by thin cutting (approved as a business innovation plan certified by the governor of Saitama Pref.)

Resin materials are also supported

We mainly process metals, but we have recently started processing resin-based materials for weight saving. (*2)

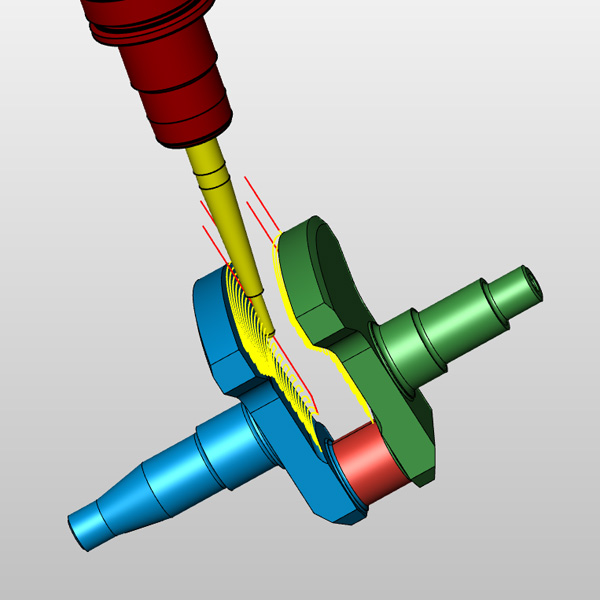

5-axis Processing

In our business, 5-axis processing is essential for providing parts in complicated shapes that are required for technical research and development fields. This processing includes some issues related to expansion of the error due to many axes used, and this makes actual processing quite difficult.

Precision errors due to processing heat and pose variations could become larger when compared to processing based on 3-axis machines. Taking advantage of our experience and technique we have accumulated, we control such errors while fully utilizing our temperature-controlled workplace and measurement environment. Therefore, our performance continues to achieve the highest level of finishing within the industry throughout a year.

Our 5-axis Processing Machines

DMG Mori Seiki: NMV5000

NMV5000 is a vertical 5-axis MC manufactured by one of the four major domestic processing machinery manufacturers, Mori Seiki. Taking advantage of this machine's feature of easy handling, we use this machine for producing parts in small lots. The table equipped with the DD motor, which swiftly starts to run, makes simultaneous 5-axis processing faster. This 500-φ table has a structure that interferes with the main axis less, being capable of processing undercut even at quite a deeper portion just on one process.

MAKINO MILLING MACHINE: a61nx-5E

This horizontal 5-axis MC, a61nx-5E, is manufactured by the largest manufacture in the industry, MAKINO MILLING MACHINE. This machine is designed as the high-precision specification by changing ball screws into fine-pitch screws, making it possible to finish multiple high-precision 5-axis processed parts efficiently. This machine, equipped with 2APC, can meet a wide variety of needs, such as unmanned operation of a number of processed parts and scheduled operation to finish two types of processed parts alternately. It also supports spring neck processing that is much in demand in making dense packing grooves. As designed based on a horizontal MC, this machine is also suitable for deep hole processing using long drills.

MAKINO MILLING MACHINE: D300

This is a small-sized 5-axis machining center for a table diameter of Φ300. The center is mainly for 5-axis processed products of accessories. It’s suitable for processing micro products using small-diameter tools (not less thanΦ0.1). Since it’s equipped with a pallet changer, it’s suitable for high-mix low-volume production.

OKUMA: MULTUS U3000

This is a lathe type 5-axis combined processing machine. It’s the most powerful combined processing machine having a turning function and a milling function. It can simultaneously process a polyhedron and do turning for cylindrical work. Furthermore, by supplementing a gear machining package, it makes the machining of gears of inner diameters and outer diameters possible through hob machining or skiving. Also, because it has a tailstock, it can process complex shapes for shaft shapes.